News Center

Hundreds of billions of connectors and sensors are embedded in massive, connected physical devices that continuously collect, aggregate, and transmit vast amounts of data. Whether it's advanced healthcare devices that remotely monitor heart rate and medication intake, automated assembly lines that allow real-time visibility of production and operation data and early warning of failures, smart home systems that can be turned on and off with mobile phones, and autonomous/unmanned driving, wherever there is power, signal, and data flow, there is connectivity and sensing.

Small sensors lead to big business. The goal of all sensors is very simple: to collect data (vibration, temperature, pressure, voltage, humidity) that can be analyzed using algorithms to make better real-time decisions. The more and richer the data collected, the better the real-time analysis. Compared with the dazzling end products, the connector and sensor companies in the upstream of the industrial chain are usually unknown, but they are the invisible heroes. TE Connectivity (TE), one of the world's largest manufacturers of sensors and connectors, is one of them, with sales of $14 billion in fiscal 2018.

87% of TE's fiscal 2018 revenue came from applications in harsh environments. Full load high-speed operation of the factory assembly line, the existence of devastating pressure in the depths of the ocean, minimally invasive surgery, high-speed high-risk racing events, the more such harsh environment is not allowed to miss the more appetite for TE, the two Mars probes "Opportunity" and "curiosity" have been equipped with TE temperature sensors, successfully landed on Mars.

"For example, in high-speed automotive networks to achieve 100M bit/ second, or even 1G bit/ second transmission rates, which requires the chipset to achieve fast data transmission, requiring the use of a lot of sophisticated cable and connection technology." TE's cable and connectivity solutions help systems achieve these high data rates." Alan Amici, the company's vice president and chief technology officer for transportation solutions, told reporters, including the Paper, at TE's CTO roundtable held in Shanghai recently.

Originally developed for use on large and expensive industrial platforms like jet engines, these electronic "eyes" and "ears" help spot problem parts and avoid failure in real work. As costs fall, sensor applications extend to all walks of life.

TE's connectivity and sensing solutions are used in everything from driverless and electric vehicles to next-generation commercial aircraft, smart factories, high-speed data centers and advanced medical devices. The company was named by Fortune magazine as one of 63 "Companies changing the World" in 2018.

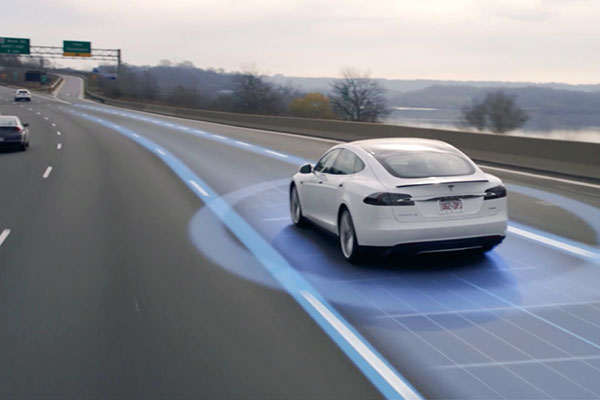

The development of autonomous driving technology has put forward higher requirements for precision and collaboration of efficient sensor, antenna and data connectivity technologies. The number of connected sensing components used in cars is increasing, and the amount of data transmitted is also increasing. In the increasing data traffic, large packets requiring high bandwidth continue to occupy a large share.

Autonomous/driverless vehicles rely primarily on lightweight radar sensors that emit lasers to detect nearby objects to determine distance and then map the vehicle's surroundings in 3D. On this basis, the unmanned system can analyze the data through algorithms, issue instructions, and then execute. As the first procedure, the accuracy of the sensor directly affects whether the subsequent decisions and instructions match the real environment.

During autonomous driving, wireless communication allows vehicles to stay in touch with each other and can monitor the surrounding environment, including pedestrians and cyclists, thus improving safety. On V2V (vehicle-to-vehicle) networks, cars send each other information about what they are doing, including speed, position, driving direction, braking, and so on.

"Autonomous driving will use a lot of sensors and require a lot of data, for example, radar, antennas and other on-board systems will involve a lot of data transmission. In addition, there is a lot of information outside the car's own system, including map information, V2V information, stored in the cloud. The question is how to achieve the transfer of these large amounts of data." Alan Amici said that the development of the automobile is increasingly inclined to build high-speed data networks inside the car. Previously, the car local connection network was used, and now it has switched to an Ethernet-based connection network, which greatly improves the speed. TE developed the Ethernet-based automotive data network, which can now transfer data at speeds of 100 bit/ s or 1 bit/ s. TE is developing the next generation of data networks that enable faster data transfer rates.

In addition, TE is developing the next generation of highly stable data connectors for safety-critical applications such as LiDAR and radar that generate extremely large amounts of uncompressed data.

As some static manufacturing in the past gradually shifts to more flexible flexible manufacturing and robots are put into large-scale application, the density of sensor layouts in future factories will become higher and higher. Industrial sensors not only require demanding performance indicators, but also have a wide variety. Taking industrial robots as an example, the types of sensors involved include: three-dimensional vision sensors, force and torque sensors, collision detection sensors, safety sensors, welding seam tracking sensors, tactile sensors, etc.

David Brown, TE vice president and chief technology officer for Industrial Solutions, believes that the smart factory of the future, which is full of sensing technology, has a lot of data that can be used by AI to help the factory make "informed decisions" and make the daily maintenance of the plant more precise. "In terms of research and development, we see two main trends, the first is that as more and more sensing technology is applied in the factory, we will be able to deploy connectors and sensors faster. In addition, the size of data will be greatly increased through images from many computers and improved sensing technology.

(Source: Thepaper.cn)

Return to Overview