News Center

In order to save energy, reduce emissions, develop low-carbon economy, and participate in the fourth round of restructuring of the automobile industry pattern, China has promoted the development of the new energy automobile industry through relevant support policies since 2001.

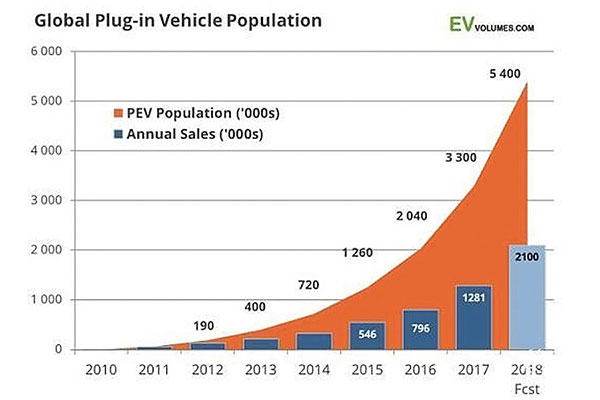

Today, as of the end of 2018, the global total sales of new energy vehicles exceeded 5.5 million, of which China accounted for more than 53%, and the shadow of new energy vehicles can be seen everywhere in the streets of Hangzhou, and the new energy vehicle supporting motor industry ushered in the golden period of development.

In the new era of new energy changes, Gaopin Automation actively absorbs advanced technologies at home and abroad, applied to the manufacturing of new energy automobile parts, in-depth research and development in the field of new energy motor electronic control, has completed the full series of product integration of core components such as motors, motor controllers, batteries/battery modules, keeping up with the pace of global automotive development.

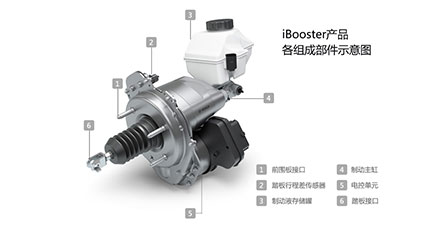

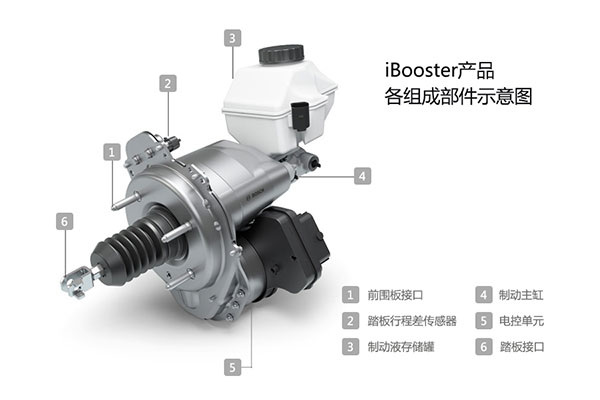

In 2018, after in-depth research and development, Bosch launched a new generation of brake booster products: intelligent booster iBooster, which subverted the brake revolution of the automotive industry and promoted the further development of the new energy vehicle industry.

Before the launch of iBooster by Bosch, in order to reduce the physical consumption of the driver, the vacuum booster hydraulic braking (braking) system is used in gasoline passenger cars, and the vacuum degree in the gasoline engine intake pipe is used to generate power to help the driver brake, and the vacuum degree is generated by the electric vacuum pump. Compared with traditional brakes, iBooster cancels the design of vacuum pump and replaces it with various types of sensors and controllers, which makes new energy vehicles free from the limitations of vacuum pumps.

The principle of iBooster braking technology is to use the sensor inside the mechanism to sense the force and speed of the driver pressing the brake pedal, respond to the driver's braking action, process the driver's braking action through the controller, and convert the signal into a signal to transmit to the motor control unit of the brake pump. After the control unit calculates the torque required by the motor, the two-stage gear unit device converts the torque into the servo braking force of the booster body, and finally drives the amplifying mechanism to finally push the brake pump to start working and realize braking.

How it works:

1. Input rod 6 generates displacement;

2. The pedal travel sensor 2 detects the displacement of the input rod 6;

3. The displacement signal is sent to controller 5;

4. Controller 5 calculates the torque generated by the motor;

5. Then the torque is converted into servo braking force by the transmission device.

6. Servo braking force, input lever 6 input force from the pedal;

7. The brake fluid pressure is collectively converted into brake master cylinder 4.

iBooster without vacuum booster features does not rely on vacuum source, replacing the traditional vacuum pump and vacuum hose, and is smaller in volume and lighter in weight of the entire braking system. It does not need to consume energy to establish a vacuum source, and only consumes power during braking, thus achieving the purpose of energy saving and emission reduction. At the same time, iBooster adopts modular design, which significantly reduces the diversity and number of parts. iBooster has strong compatibility and is suitable for a variety of vehicle models. Customers can use the same product iBooster for the entire platform development, reducing engineering development costs. Bosch claims that iBooster is superior to conventional braking systems in terms of braking distance and response speed under the same vehicle conditions. From these aspects alone, the development prospect of iBooster is very exciting.

Now, as a pioneer in the domestic intelligent manufacturing industry, Gaopin Automation has naturally joined the tide of new energy, and has reached cooperation with a number of well-known companies on the iBooster project. The iBooster electronic booster assembly and testing technology independently developed by Gaopin is adopted:

1.Riveting, airtight test, push rod tensile test, grease coating, pulling force test and other processes

2.Quality traceability is achieved through the intelligent production line Management system (G-LMS system)

3.Equipped with Bosch Rexroth transmission line, German control system and other hardware equipment

4.Apply MES system to build digital smart factory

And other advanced processes provide the best solutions and technologies for iBooster electronic booster assembly and testing.

In the future, Gaopin will continue to follow the trend of The Times and the development trend of the automotive industry, continue to deepen research and improve technology in the assembly of new energy vehicle components such as iBooster electronic booster, and strive to become an important "booster" for the development of the global automotive industry.

Return to Overview